|

|

Geofoam SNP

Geofoam SNP™ Cellular Concrete can be produced quickly and easily on site by mixing preformed foam having the consistency of shaving cream into a portland cement slurry. The combination can withstand vigorous mixing and has been pumped well over a mile with little loss of cellular structure. It can be installed at a rate of more than 100 cubic yards per hour, has excellent workability, and typically sets in the same time as normal concrete.

Features:

- Lightweight

- Inert

- High slump (virtually self-leveling)

- Broad range of densities and compressive strengths

- Excellent freeze-thaw resistance

- Low water absorption and low permeability

- Insulating

Benefits

- Provides insulation (can contain up to 80% air)

- Rapid installation

- Economical load reductions versus alternatives

- Long lasting and stable

- Places easily by pump

- Positive fill

- Absorbs Shockwaves

Geofoam SNP

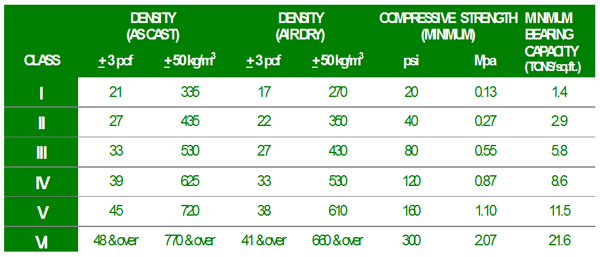

Cellular Concrete Neat Cement Density Strength Chart

The compressive strengths shown are approximate. As with ordinary concrete, the strength at any given density and mix proportion will also vary with the type of cement and the final water content of the mix. Substantial increases in strength will result by reduction of the water/cement ratio, as is possible with efficient mixing equipment and by curing in low-pressure steam. Other admixtures such as foam compatible dispersing agents and water reducing agents may contribute to strength increases.

Typical mix designs illustrated above are based on water/cement ratio of 0.50

Method of ASTM C495 used form compressive strength Testing of Lightweight Insulating Concrete.

Here is a reveiw of the freeze/thaw, permeability and water absorption specifications:

CO EFFICIENCY OF PERMEABILITY*

|

CLASS II

|

CLASS III

|

|

Maximum Cast Density, PCF

|

18-24

|

14-20

|

|

Co efficiency of Permeability, k, cm/sec

|

|

@ Effective Confining Stress, 2.5 PSI

|

4.7 x 10 -5

|

1.5 x 10 -6

|

|

@ Effective Confining Stress, 18PSI

|

1.9 x 10 -5

|

5.4 x 10 -7

|

*As determined by method of U.S. Army Corps of Engineers, EDM, 1110-2-1906 and ASTM D2434

WATER ABSORPTION*

|

CLASS II

|

CLASS III

|

CLASS IV

|

|

Maximum Cast Density, PCF

|

30

|

36

|

42

|

| % Water Absorption After 120 Days

|

20

|

16

|

14

|

*Long term total immersion as percent of cast density per method of ASTMC796

RESISTANCE TO RAPID FREEZING AND THAWING*

|

NUMBER OF FREEZE - THAW CYCLES

|

CLASS II

(30 PCF)

|

CLASS IV

(40 PCF)

|

|

30

|

98

|

98

|

80

|

90

|

95

|

|

120

|

86

|

90

|

|

330

|

70

|

79

|

|

Relative "E" Percent at Cast Density |

* As determined by methods of ASTM C 666 modified to allow for the insulating properties of GeoCell. |

|

|

|